-

Posts

377 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Redline Racing

-

-

Why not weld it up deck cylinder back down and never worry best choice. Epoxy will be so thin it will be easy to chip off or scrape when cleaning gaskets.

It's between both cylinders so put good cyl on first put a small bead of 1211 between cylinders and install damaged cyl. It will never blow since they are right next to each other.

-

1

1

-

-

STFU Tyler. If you need anything Tom let me know.

-

I just checked my emails and in Aug of 2015 when you got the Mtr you said you did a leak then and had no leaks. You said it had diff plug colors left to right. With left side being tad wet and right being dry. I give every Mtr to leave shop a leak down test I know it wasn't leaking when it left here and I guess you found same to be true.

-

I would have no problem helping any customer if they have a problem. I don't believe I have been contacted about any issue so it's hard to help. I am sorry for delay on motor and then you have to work on it.

-

People don't realize how long it takes to properly build a mtr. It always takes way longer then it should no matter what. There's a stripped hole, broken stud, supply chain delays, machine shop issue,........ Goes on and on.

I try to be honest with customers if I haven't touched it I tell them. If they want it back and ship it else where I'll do it.

My phone rings 20-40 times a day I got 200 emails I haven't looked at and I got 20 mtrs sitting here. I try to balance all sides of business but it's very tough. Do I meet all deadlines no have I had mtrs longer than a year of course.

Anyone who has been to my shop or any other sponsors shop knows we as not sitting around getting rich off this. We work 60++++ hrs a week at 6-7 days a week to make our living. Most my customers prob make more than I do and work way less.

My point is if Redline or any other sponsor doesn't answer the phone, return an email or call you back its not personal. It's the fact that we are overwhelmed with daily tasks and prob couldn't take anything else on. Not the fact that we don't value our potential or current customers.

I appreciate every customer big or small for there business. Thanks Cam

-

11

11

-

-

Thanks guys!! I try to do my best but I can be very slow at times. Thank you to all my patient customers past and present!! Thanks Cam

-

2

2

-

-

Will sell cheap.

-

I did quite a few 120 rod cubs and 125 rod DM's back in the day. IMO it was a waste more expensive and weaker cranks, thinner cases. With a twister crank it's just a bigger rod pin home on same wheel diam so it has less metal around OD of crank and pin area. CW 's won't go that thin on OD/ pin area so they use snap pins (step pins) to do the job. I've used Louie's with no issues on crank wheels but I've broke few step pins.

Due to bigger bottom rod OD you must trench cases thinner to get all to clear and rod has to be trimmed. So now we have a more expensive rod, thinner cases and depending how thin rod is trimmed it can be weaker. All this for what I saw was little to no gain.

Only plus I ever liked was the flat top KTM pistons you can run with 18 mm pins. I liked those pistons.

-

Usually if it shifts correct part if time and not well other times it is rider related. We know all parts are new and has a pro mod so mechanical it should be good. So I would say if you launch in 2 nd and go to shift to third it's a fairly quick shift so you may not be letting shifter drop down to catch the star for next up shift.

Or possibly it's a little low geared and it's spinning tires way to hard. Try dropping air pressure way down or changing gear ratio.

Or call me and we can go over other scenarios that could be going on.

-

2

2

-

-

I'll do 175 shipped on pair? Pm me if interested. Thanks

-

No studs or bolts need to be removed by you. Please clean cases as good as possible.

-

1

1

-

-

It would take me a few weeks to get it done. I'm pretty far behind on projects in the shop right now.

-

2

2

-

-

I have answered all these questions in emails. We raised cylinder to 190* with a little flatter exh shape. We provided a .020" base gasket. With 24cc domes we usually see 11.8-1 compression with 20cc domes it will be about 14.5-1. This is plenty of compression @ a 190* exh. A compression gauge is great for a reference point but not very accurate.

-

1

1

-

-

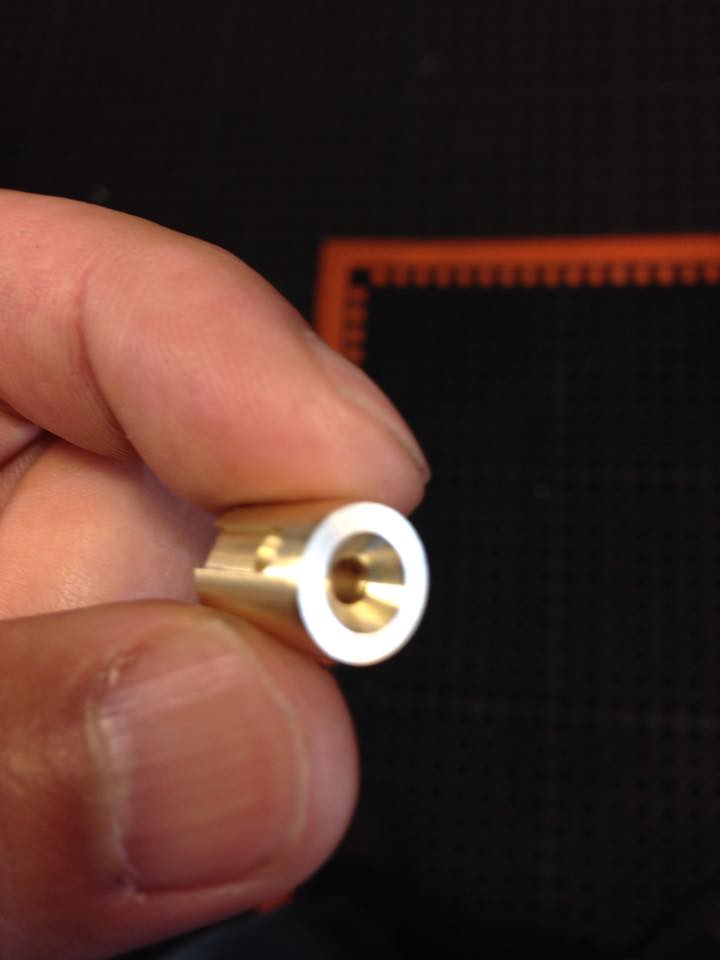

Redline Racing would like to introduce our very own Keihin PWK pumper carb mod.

This modification will allow you to run a pump with your current PWKs or a new set you purchase from us.

The old seats are removed and replaced with our precision machined seats. Your needles will be replaced with a set of pumper carb needles.We tested the setup on the 24DM we recently dynoed and they work great with excellent fuel flow.

Pricing is as follows:

Pumper Mod - $100/pairInstall precision machined seats

New pumper carb needles

Alky Mod - $150/pair

Install powerjets

Drill carbs

Keihin 41PWK - $525/pair

Keihin 39PWK - $375/pair

-

1

1

-

-

Greens family the Palmers are there to.

-

1

1

-

-

I can under cut this price.

-

1

1

-

-

If that's the basket you bought its not a Mattoon. It looks to have alum backing plate in it to, Those tend to come apart after awhile and ruin stuff if not caught.

-

I wouldn't say they will make more low end then a PT mid but it will be very close and blow it away in HP. PT mid pipes are very good low pipes but in my experience they provide low hp numbers.

-

For a duner these pipes are a great pipe. I've ran them on many Mtrs as tests. Every mtr they made 8-10 hp better up the face, but they do sacrifice the rpm. Usually they rev to about. 9200 rpm. Cam

-

1

1

-

-

-

Thanks for all orders placed! Cam

-

MacRacer1 I can get billet mik bowls if you need.

-

They are silicone filled. So they are frost proof.

-

1

1

-

-

Putting a garden hose over a pencil? Leave locos love life out of my sales please. Thanks cam

-

1

1

-

Back from the Dyno (Need Advice)

in Banshee Repairs and Mods

Posted

You are way rich especially with pwk as carbs. I'd guess 40-ish pilot low 150 main. I've dynoed Kevin's Mtrs they make power if properly set up.