-

Posts

2,897 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Justintoxicated

-

-

Different LEDs and different housings and drivers... A lot of the ebay ones are not waterproof and use cheaper lenses and optics and lower binned LEDs, but not all of them.

-

Just FYI, in Cali when you get a replacement frame they simply rivet on a vin plate into the front of the frame. So once you get it back, there might be a simple solution like that to prevent it from happening again.

-

Just buy my friends 7 mil cub, it's in great shape with a perfect frame. It's been sitting for 3 years and he wants to sell it. Then you will just need to change the domes in your head so you can run 91 and you will be done.

-

I think they sell those rainbow flags on ebay.

Off topic!

-

Could be the amsoil. Castor 927 does not mix with synthetic. Never mix them together. I prefer synthetics to castor 927, although I love the smell of 927

If your jetted rich, 927 will leave a ton of carbon buildup on the pistons, and since I don't re-jet every time I ride I prefer synthetic. Amsoil Dominator is good stuff I used to run it all the time, but have been running Maxima Synthetic lately because I can get it a lot cheaper.

If your jetted rich, 927 will leave a ton of carbon buildup on the pistons, and since I don't re-jet every time I ride I prefer synthetic. Amsoil Dominator is good stuff I used to run it all the time, but have been running Maxima Synthetic lately because I can get it a lot cheaper. -

So I'm building some LED whips for fun and now I just need to figure out the best method to attach a flag to them. Should I be getting some cheap RMATV replacement flags and adding some metal eyelets to them?

Or should I be looking for a flag that will fit over the whip then use some zipties or clamps or grommets to hold it in place?

What I have so far.

RMATV Flag + Eyelets + Zipties?

https://www.rockymountainatvmc.com/p/1032/-/148995/Tusk-Orange-Replacement-Flag

+

http://www.harborfreight.com/103-piece-1-2-half-inch-grommet-installation-kit-30037.html

Or this style flag?

http://dwflags.com/store/view_product.php?product=01flag

Thanks!

-

I can feel the love

-

Im tellin ya the oven is the prefered method but if you dont believe me you can ask on the honda sites and they will say the same thing. Aotopart stores sometimes rent tools. They may have a bb puller

I tried o'rielly they didnt' have one, need to check pepboys and auto zone still.

I'll try the oven, i do believe you, I just don't have high hopes

-

I'll try the oven soon, but I don't see it working any differently than heating the aluminum case around the bearing with a torch...

At this point I'm tempted to just give the cases and all the parts to the shop and tell them to finish it for me. 250R transmission sucks to disassemble compared to the banshee. I still need to buy a new counter-balancer and bearing, a few bolts that stripped for the motor mounts, and a bunch of other misc stuff... I think I might have been better off just selling the rolling chassis or just throwing the whole thing in the trash minus a few parts. I just don't have the time for it.

-

of course your not trying to save the bearings. the main concearn is not damaging the cases or fuk up the bearing bore. thats why you heat the cases in a oven to around 250ish. that reduces your interference fit and allows the bearing to pop out with little effort. pressing them out isnt much better than hammering them out, either way your still trying to force the bearing out of a .003" or so interference fit.

if you look at the bottom of the shift drum bearing it likely has a lip between the bearing and case. this is where your BB puller will grab. whether theres a inner race or not makes no difference. you can probly also pop the needles out and try grabbing it at the top lips but usually those type of bearings have a larger lip at the bottom specifically for grabbing with a puller

the tab screws have loctitie from the factory. heating them will do no good as that only makes the screw bigger. a qaulity impact driver like snapon and 1 or 2 taps from a dead blow rubbet mallet is all that should be needed. if you strip out the philips head youll be fuked big time

if you dont have the proper tools you might want to find somebody that does

Yes I used an impact screwdriver (although a cheaper one than a snap on), didn't do shit, those screws are in there damn tight. I have removed red loctighted screws that came out easier before, and this DOES require heat to melt the loctight.... I might have to try drilling them out with one of those screw extractor bits, but I'm trying to contact some places to see what it's going to cost me.

I don't want to spend a fortune on this thing as I just want to get it rebuilt like new then sell it. Whoever put sand in my engine is must die!

Can you please link the proper blind bearing puller that can grip the needle bearing? I didn't measure the ID but I think it's about 2-3" I'm thinking a set like this would work, but it's $200 http://www.amazon.com/Internal-Extractor-Bearing-Puller-Remove/dp/B00KOBRQ1Q/ref=sr_1_2?s=automotive&ie=UTF8&qid=1433301765&sr=1-2&keywords=3%22+blind+bearing+puller

Again I did heat the cases (not with an oven, with a torch) Heating in an oven would also heat up the bearing itself, you don't want to heat the bearing according to everything I read, just the case so it can expand and the bearing falls out.

I watched several youtube videos showing people doing this, however it did not work for me, so I had to tap the bearings out with a socket on the inner races while the case around them was heated. Putting the case in the oven would not have don't shit if the torch didn't work IMO.

-

4 lb. Sledge? Are you retarded?

Don't have to smack it as hard as with a hammer and has a larger head to avoid smashing the crap out of my hand, so I switched to the sledge, it's what a friend suggested. Anyways neither one is hitting it hard enough to free up the screw head.

-

that's what I was using, tried a regular hammer on it before switching to the 4lb sledge. I'm afraid of twisting the heads off the screws at this point. The largest bit I have fits in the screw head about perfect, or it did before it started to deform.

-

Luckily I've got a set of those $500 cases!

ESR has them in stock too. Is the bearing option for $100 to have all the bearings installed?

-

First, those cases are tight tolerance. You are nuts for aimlessly pounding them out instead of finding a press to use for 5 minutes.

Second, when removing anything with heat, you don't torch the object inside that you're trying to remove. It's simple physics. Heat expands the metal, so by torching the bolt it swells inside the threads making it harder to remove. It also softens the bolt so it makes them easier to break off. TORCH THE SURROUNDING AREA.

Third, fuck it..... You got it figured out.

They are blind bearings so a press isn't going to help, a BB puller will work for one of them, but shit that's another $110 for the tool, and I think a different kind of tool is needed for the one without the inner race. For the 3rd bearing I tried both heating around the screws and the screw itself different times. I torched the screw itself in case it was red loctighted in there. Neither helped they do not want to come out. I was able to remove all the other screws in the cases that were similar, but neither of these will budge. The way I heated around the screw was to heat up the buldge they go into on the opposite side of the case, than without getting too close to the screw a few passes around it.

BTW getting a shop to remove a bearing on a press isn't cheap around here. Called around pricing what it would cost to get a bearing removed from a geo methro hub and it was about $80 (actually only one shop would do it, everyone else said they only do complete repairs), but after 2 months I finally talked to a friend who knew a friend and he did it for free. 2 months though!, next time I will just pay the $80.

I know a shop that might be able to help that is a little more reasonable for ATV repairs. I have a feeling the screws might need to be drilled out though, and I'm starting to consider buying some new cases for $500 instead

-

banging the bearings out is always a bad idea. should of just told the ol lady to go out for the night and then used the oven

2 of the bearings you need a blind bearing puller. the other one you need to take those 2 tabs out

I used a propane torch and heated the cases, then pounded them out. They were in there pretty good, even with heating the case around the bearing. I'm not trying to save the bearings anyways they are all trash.

I can't get the 2 tabs out because the screws are frozen, I heated them up very very hot, took a 4lbs sledge hammer to my impact screw driver and they will not turn at all. I put the cases on a 3/4th thick rubber mat laid on the concrete to help absorb the blows from the impact and sledge..

Also even with a blind bearing puller I don't know how to get the needle bearing out as it has no inner race.

-

So I finally broke down and bought a nice torch to try to torch the bearings out. Well it didn't work, but with some heat and a large impact socket I was able to tap most of them out.

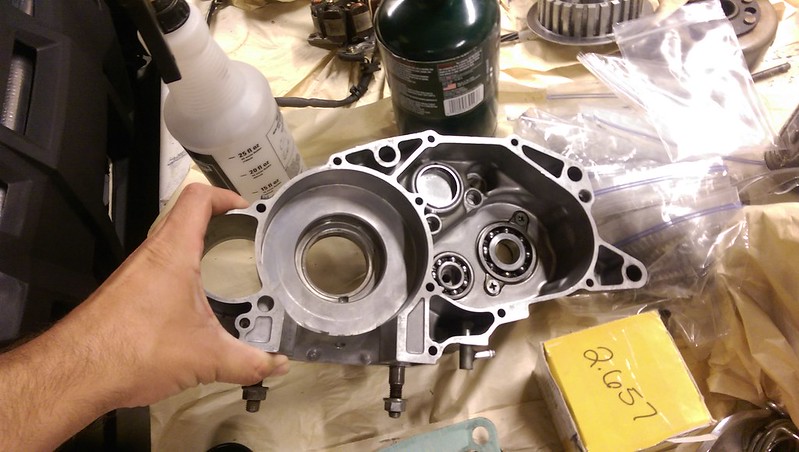

However I can't get these 3 bearings out any ideas?

I tried heating the screws up and using my impact driver to break them free but I couldn't get them to budge.

Can't get these bearings out. by glamisduner, on Flickr

Can't get these bearings out. by glamisduner, on Flickr -

I have both, HID's can and will throw farther than LED's when designed properly. But LED's are typically a bit brighter than smaller less efficient HIDs. Most HID's have a slow warm up time. Some cheaper LED's will not be as efficient as HID's as well, due to crappy reflectors or lower binned LEDs, but it does seem LED's have caught up to HID for the most part.

I like my rigid 10" lightbar with driving beam pattern , only uses 50 watts and nice beam.

Unless you really need to save weight, get a good battery, it's nice to have the lights stay on when you kill your bike due to having to brake too quickly.

-

I like marine-tek grey , holds up to fuel great and I've used everything else and solely use this now. If I have to fill cases for trenching I use Wes - epoxy with aluminum etcher just cause of the ability to mix greater amounts at a time Wes systems have a large variety of uses and products, sorry for going on tangent

Did you mean marine-tex?

Is this the right stuff? http://www.amazon.com/Marine-Tex-Might-Repair-Ounce/dp/B001446LKO/ref=sr_1_3?ie=UTF8&qid=1427398911&sr=8-3&keywords=marine+tex

I read good things about devcon, but that stuff is like $80 for a lb. May as well just buy new cases at that price point lol.

-

What would be the best product to fill the gap on this case. JB Weld? MSR Aluminum Putty?

Thanks!

-

when you convert to DC you will lose some power, even with a battery I would try to stay around 120 watt total tops, less would be better.

My phone isn't very good at night shots with hy dynamic range but here is my 10" handlebar mounted LEDs I got for dune riding. They are nice nice tall floody beam. I'll try to get better pictures with a real camera soon. The beam is more floody and less spotty than it looks, but the weeds are too with too much light on them so the camera darkens the rest of the picture. Still neighbors fence is pretty far away. This light bar is 50 watts

Just the light bar.

10" light bar by Glamisduner, on Flickr

10" light bar by Glamisduner, on Flickr IMAG0251_1 by Glamisduner, on Flickr

IMAG0251_1 by Glamisduner, on Flickr -

If u epoxy it, grease the bolt put it all together then epoxy it, also bearings 24 hrs in the freezer , cases inside at room temp 65-70* and they will almost fall in light tapping if anything

I was thinking to just put the dowl pin in place (it's a fairly tight fit), maybe put some grease and suran wrap over it. Then, fill the broken area with alumbond epoxy http://www.amazon.com/Hy-Poxy-H-45-Alumbond-Aluminum-Repair/dp/B001J9MO6O/ref=sr_1_1?ie=UTF8&qid=1427329104&sr=8-1&keywords=aluminum+putty.

Then shape the top and new built up area flat with file / sandpaper.

What do you think?

Yea, new bearings in the freezer, and maybe heat up the case where they go. But how do I get the old bearings out? Torch the surrounding case area? or will I need to purchase a blind bearing puller? They seem to be priced around $100

-

I found some cases on ebay for $350. That or maybe I can just add some metal putty, and re-use the ones I have. Since I will be replacing all the bearings, i just want to be sure I have them pressed into the right set of cases, the bearings are all pressed in unlike the banshee.

-

So you have power going to the ignition coil, but not coming out of it? Yet your sure it is working? I guess I don't understand, sounds like the coil to me.

I would ditch the parking brake too, those have never been kind to any banshee owner, ditch the parking brake and get a blockoff, if the switch inside the brake is stuck on it will auto kill your banshee spark if the tors is connected. Usually the TORS itself wasn't the issue it was actually the parking brake switch that connects to the tors from my experience, switch would get stuck event though the parking brake was released. Sorry if your already knew this, you said you check it, but the best way to check it is to get rid of the whole thing and see if you still have no spark. I believe you can check to see if it is the issue without a blockoff plate just disconnect the box under the fuel tank on the left side.

-

keep that broken piece and have someone weld it back on there

That will just make it so the alignment pin does not fit again.

Air filter advice

in General Banshee Discussion

Posted · Edited by Justintoxicated

I hate K&Ns but your options are pretty limited on Banshees due to limited space and the need for a high flow filter. I like the new reusable synthetic dry flow filters better, but they need to be pretty big to flow. Go with a K&N and outer wears if your stuck running pods, or really even if your using the airbox. Yes dust can and will get past it, but at least it's a 2-stroke with an easy rebuild.