-

Posts

402 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by THE358BANSH

-

-

As the title says, I'm looking for a -1 or -2 roundhouse swingarm, cheaper the better. It doesn't have to be pretty or fancy, just short. Thanks, Evan

-

I would be leery of using the spark plug threads for your centering. I have seen a few that are .040" off center compared to the bores. Other than that it looks pretty nice for what you are working with.

-

The best way is to run a relay off the light switch. The switch and wiring up to it are too small for the type of current that some of these lights draw.

-

Blake,

The RZ topend runs strong and has a bunch of low end compared to my play ported cylinders. Thanks a bunch for the parts! Evan

-

Is the cover PC'd or painted? How much for it without the lock up? Thanks!

-

i tore my engine apart today and i got a little confused. it doesn't have a seal in between the crank bearing and the case? how is that possible?

In between the center crank bearings there is a Labyrinth seal.

-

Could you get away with using a nylock jamb nut? They are probably a quarter inch shorter than the standard nut.

-

To add some more to this thread about piston dome volume I played around for a bit today while parts were washing. I weighed a 65.5mm 795 series Wiseco with no rings, no wrist pin, and no wrist pin bearing. Total weight of the box stock piston was 207 grams. I chucked in in the lathe and turned .160" off the dome to make it a flat top. Total weight of the flat top piston was 188 grams.

Original piston weight 207 grams - Flat top piston weight 188 grams = 19 grams of material removed

19 grams removed x .0022 lbs/gram = .0418 lbs of material removed

.0418 lb of removed material / .0980 lb/in3 weight per in3 of aluminum = .42653 in3 of material removed

.42653 in3 x 16.387 cm3/in3 = 6.989 cm3 of piston dome volume

Obviously that number will change with piston series, bore size, and if the dome angle as been modified.

-

Question for the original poster, how do you like that BiMotion software? I have and use TSR and like it. I never found the computer calculations of cc volume to ever be what the actual cc volume is that i measure with my burette filled with kerosene. I just do it the trusty burette way and know the actual. Some the calculations on paper or in theory, don't quite seem to equal what the real world measurements are.

I have never used the BiMotion software. The TSR software is the universally accepted standard, but sucks now because Tom is no longer handling everything. I would like to get my hands on a copy at some point in time to do some comparing. If I remember correctly the TSR software also has a recommended octane starting point based off inputted figures and dome profile, right? The burette has its issues also with fluid sometimes not getting into every crack and crevice, along with people getting carried away when applying the grease seal. I think the best way to figure all of this would be FPV the dome with a spark plug, then account for other volumes by software/calculation to arrive at a compression value. Then use software of choice to determine the MSV of the entire package... Evan

-

I come up with 6.68cc dome volume for that piston. Also don't forget to calculate deck height, piston clearance and top ring height into your figures as these will change your ratio's quite a bit.

As for your question on max UCCR to run on pump fuel (or any given fuel for that matter):

There are too many variables to say "this maximum value will work", this is why recommendations are usually on the conservative side. UCCR, CCR (trapped ratio), MSV, elevation, and port/pipe efficiency are just some of the factors that will dictate what octane of fuel your engine will require.

But, as a direct answer to your question: With properly designed domes I have run UCCR approaching 15:1 on pump fuel at our elevation of 5,000"

-Brandon

Thanks for the reply Brandon. Would you care to share how you came about that figure? If you don't want to I understand...

-

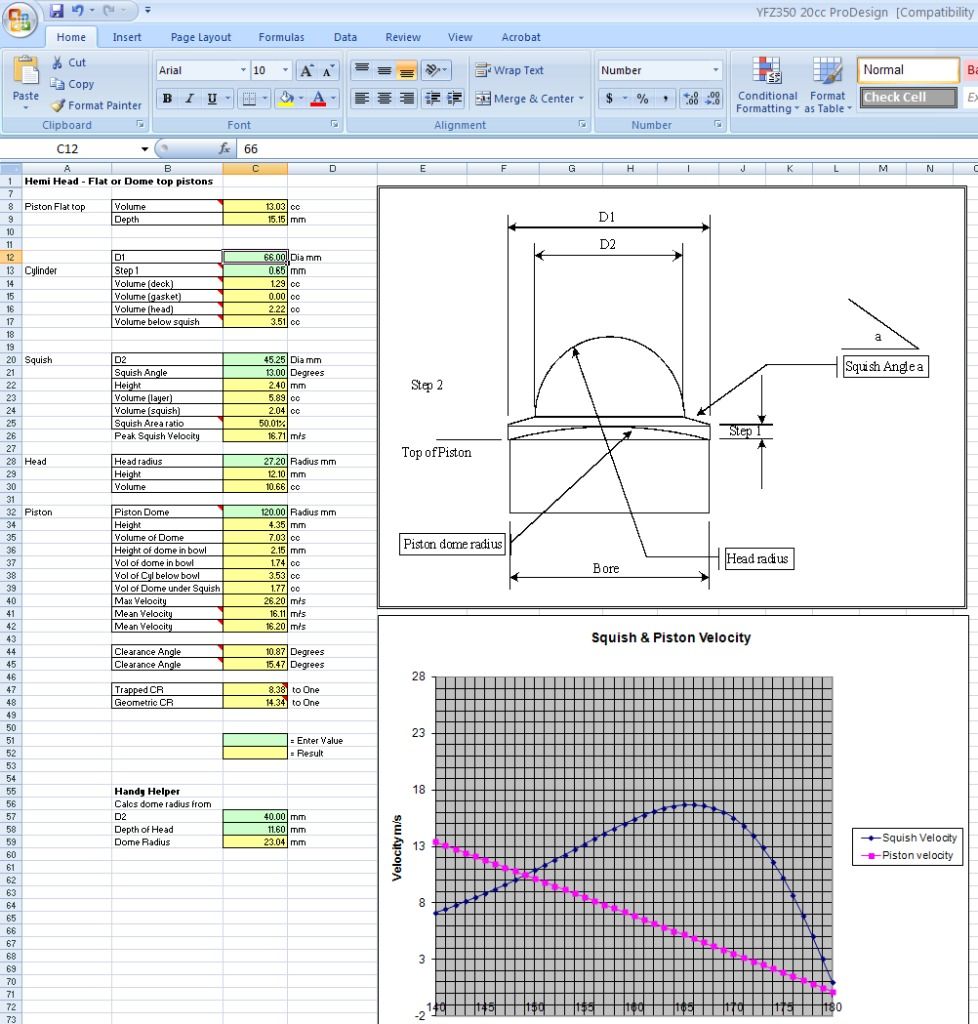

Everything looks good minus the piston dome profile. Assumption there is a constant radial profile over the dome, which is incorrect. You will notice playing with your value inputs that any small change in that dome volume has a radical effect on calculated UCCR. Once you have the volume for the piston dome, it will come back into alignment.

Great work so far though. Wish more people would take to the books before guessing and hoping...........

By the way, where did that calc come from? It looked familiar so I went through some of my old files and there it was. I have no data on it so just curious where that ever came from.

Brandon

I don't remember exactly where it came from. I want to say either the old MacDizzy site or a RZ350 forum, one of those two almost positive.

As for the dome profile, I just went next door and looked at a 795 series for a 65mm bore because it's all I have around now. I measured it up and I am coming up with 10.32cc? Seems a bit far out and in the wrong direction to me...

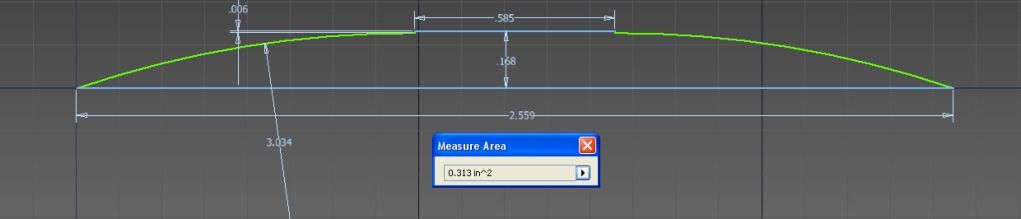

As best I can measure here is the cross section of the piston dome profile...

-

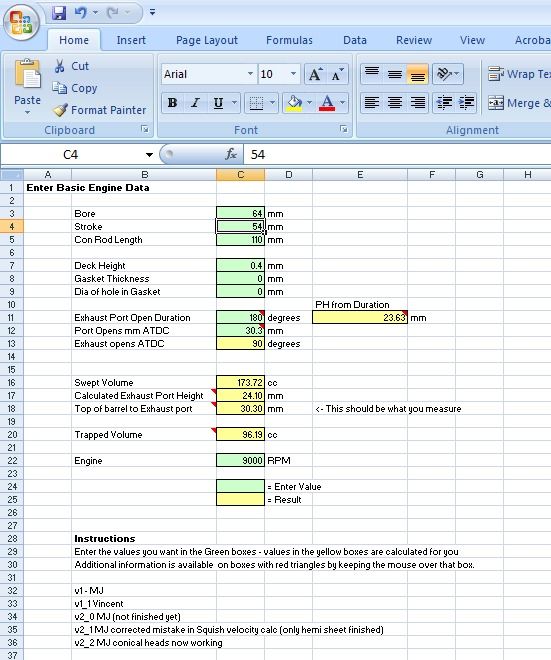

Stock Banshee numbers:

64mm bore x 64mm bore x .7854 x 54mm stroke x 1 cylinder = 173,717.9 cubic mm

173,717.9 cubic mm ÷ 1000 = 173.72cc swept volume for one cylinder

Flat plat volume of CoolHead dome is 20cc with spark plug crevice volume

Piston dome volume of 64mm bore piston with 120mm dome radius = 7.0cc

20cc flat plate volume - 7.0cc dome volume = 13cc trapped volume @TDC

(173.72cc swept volume + 13cc trapped volume @TDC) / 13 cc trapped volume @TDC = 14.36:1 uncorrected compression ratio

The other option if you have a super computer...

-

I would like to see your math on that. I am not calling you out, I just want to help you on the numbers since you seem to have the ambition to do it the right way.

Thank you sir, be right back with some info all fancy like...

-

What types of uncorrected compression ratios have you guys ran on pump gas with proper head design? I'm trying to decide on whether to run pump fuel or stay with VP110 for my new build. The design of the head is pretty critical so I am looking for people running tight squish(.036"ish), squish bands around 50%, an nice hemispherical domes(no tubs or toroidal stuff). I have heard of up to 15.76:1 with +4 timing @1000 feet of elevation in some drag applications. Albeit that application was not ran for long periods of time whereas mine will be.

Looking at your typical Banshee(64x54) with proper squish and a "20cc" dome our UCCR is 14.36:1 and is well known to run with +4 timing on 93 pump fuel with proper jetting all day long. How much further could that UCCR be stretched before having to reduce timing or start mixing fuel? I figure if I have to cut fuel I'll just say screw it and run straight VP110 with the timing and compression to match.

Also, since I touched on the full race gas builds. Where do you think the tradeoff occurs between high compression and pumping losses causing the engine not wanting to rev out? Where would the cut off of UCCR be in a full drag build with a good amount of exhaust duration(200+), decent timing, and 110 motor octane fuel? I have two different domes designed currently, one for 93 and one for 110 and both of them have great MSV numbers. What say you? Evan

-

I tried to explain the thoughts that have been thrown around in this thread to a local guy a while back and got the deer in the headlights look. What you guys are working with has been refined over years in the drag racing market. The only thing that I see that most are overlooking is when they spread weight out using two different weights on three arms is not considered a multistage setup. A multistage setup has the inner hub move in multiple steps to apply different pressures and is commonly used in a "slider" or "glide" clutch.

When spreading weight out on three arms each you effectively have the same plate load as six equal arms, except now you are unevenly loading the inner hub. If you can, it is always better to run six equal weights rather than two trios. Never run three pairs of weights on a six stand clutch, reason being goes back to even loading of the inner hub.

Lever size and geometry has a large affect on how the clutch operates also. If you really want to take your program to the next level, contact Mike Sullivan at Applied Physics. He writes clutch software and is a fantastic resource. Say you knocked the tires off on the gear change but the launch was nice. His software will let you know the relationship between base and counterweight to keep the same plate load at 6000rpm, but have 5% less plate load at 8800rpm to get through the gear change smoother. Red line is the new setup with 21 less grams of weight and 242 more pounds of spring pressure. Blue line is the original setup with 700 pounds of base and 104 grams. All this theory applies to quads, just on a smaller scale. All the numbers are for your specific clutch, those were just an example obviously.

I posted a picture of one of our clutches from the ProMod we race. Anyone notice any similarities? It was apart for service, inspection, and certification so the hat is off but I still think everyone will catch on...Evan

-

I never got the chance to run them, just stashed in the house. I sent them to Cam to be checked out and set up as he cut my trans but after doing so just decided to build a serval. Trying to re-sell to offset my costs a little.

Would you be willing to separate some of the stuff? I don't need most of the things since it will be going on the EFI quad. Mainly just the PPV-RZ, cylinders, powervalves, controller, servo, cables, etc. Let me know and we can probably work something out right quick...

-

Hey Evan,

Haven't seen you around the forum in a while. Any progress on that custom frame!?

It does use the 795 pistons, the stock head is cut to accommodate the added stroke, I do not know the cc of the domes off hand but I do know that when running it ran on pump 93. The power-valves are super smooth and turn easily by hand, really a well maintained set up. When mic'ed with a digital caliper the bore reads 65mm.

The frame has been on the back burner for a bit. We exploded the clutch in the racecar and did a bunch of damage, then after getting it fixed a few weeks later we managed to smoke the wall. My year has been kind of busy so far... Have you ran the topend or did you buy it and stash it? I had a small accident on the lathe with my other jugs when I freshened my motor this spring. I'm on borrowed time with them so I am weighing my options to convert to RZ stuff now...

-

Do you still use a 795 series piston in the RZ 4mil stuff? What is the actual bore right now? Stock head cut for the stroker? What CC is the dome? Powervalves smooth and not gummed up?

-

Hi, looking back through here, I didn't see where you mounted the O2 sensor? Is there any discussion of choosing a location?

Thanks!

There was talk back in post 34. I have since changed to a set of R2s and have the sensor in approximately the same spot. Until I tell them, most people never even know it has one one it...

-

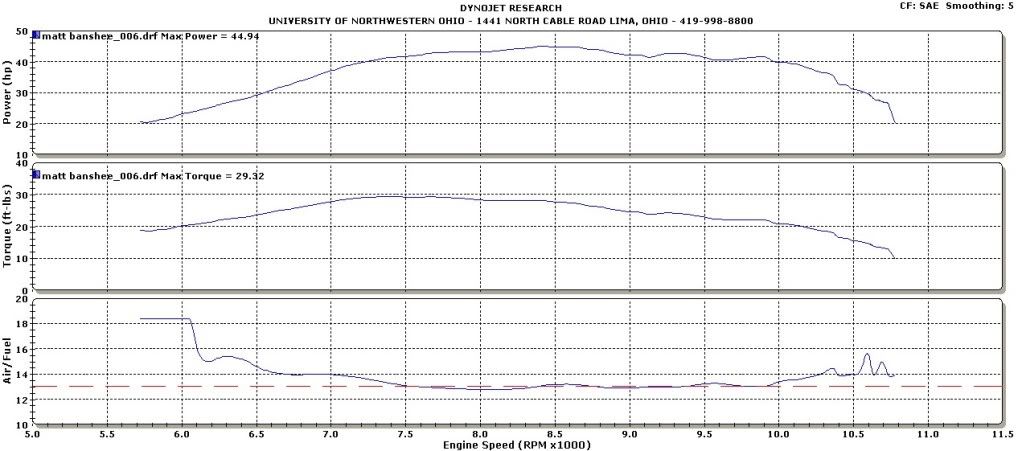

Could it be that the throttle bodies are to restrictive? High Gain tuning does something very similar(But are very shady to work with), and they were going to build a 144cc two stroke with a 39-40mm throttle body with twin injectors. 29ft lbs of torque is nice, but 44hp is near stock, and this is far from it. Again I have nothing but support for this build. Whats the gas mileage like?

I doubt the throttle bodies are too restrictive. They are 38mm straight through and also have a CV slide stock. I recently built a set of slide stops that lock the slides in the open position. It didn't really seem to make a difference on the butt dyno, but it sure does sound badass now! Richard from HGT said a lot of things and you saw where that got him. He seemed like a very knowledgeable individual, unfortunately he liked to tell people that more that prove it. That dyno graph wasn't mine, I just pulled it out of the dyno section to aid in a visual for the air/fuel description. As far as fuel mileage goes, I guess it's okay as I never really paid much attention to it? Our riding group has everything from a stock 700XX to a 60hp LTR and we are always filling up right about the same times. Judging off their numbers and the odometer from the RZR, I would say in the neighborhood of 60 miles per tank while trail riding.

After reviewing this thread, I have come to the conclusion that Zillafreak could spend the rest of his life setting up his EFI and it's still going to fail.

What ever happened to him? I haven't been on here much lately but he seems to be a ghost?

exactly what i told him. the358bansh did it in probably the best way out there considering the lack of support for something like this and a mega/microsquirt will do anything a banshee will ever need and yet zillafreak is doing everything completely opposite.

Thanks brah!

-

ever have the same setup dyno'd ? so carb vs efi ? just too see ?

The last time I had this engine on a dyno it was a 4mm with a Graydon intake and single Keihin, after I switched to the dual Lectrons I never ran it on the rollers again. In the next month or so I would like to go down to Janssen Motorsports and throw it on for an afternoon just to play.

-

That was an awesome read. Nice work, bike was super clean. It kind of sucks to hear that there isn't really an increase in power. Does it respond like a FI bike? I went from an 02 R6 to a 06 zx6r and that was a huge difference.

Thanks! I never went into this deal for a gain in power. If the mixture is correct with the carb, and the EFI is at the same mixture the engine will make the same power within a percent or so. The biggest factor with the injection is that I can control that mixture at 144 different points in reference to RPM and throttle position. If you look at any two stroke dyno graph, the AFR is a compromise at best. The AFR in the picture below starts lean as all two strokes do before getting on the pipe, and then in hunts above and below 13:1 until the over-rev where it goes lean. Now notice the correlation between the AFR and hp/tq. When the engine dips rich power goes flat and then when the engine surges leaner it starts gaining power. I can make the AFR curve flat as a board, and as a result the engine will make more power under the curve, and make that power more smoothly which translates into an easier riding wheeler with better responsiveness.

HI Evan

Good to hear you are still running the beast. Well it still looks like you are working through some small problem that come with custom set up. But still having fun doing it. I hope to see the GOPRO clips for the weekend run.

WFO

Yep, there will always be some tinkering needed to finesse everything. I knew this coming into the project and it hasn't been too bad so far, but then again I tolerate a lot more than most people.

oh your wideband, you haven't had any issues with it burning up or getting coated with oil?

The only issue so far was the controller itself having a malfunction like I said above. I run a medium length bung with a HBX-1 from Innovate to keep the sensor tip clean and slightly remote from the oil. I have run approximately 75-80 gallons of fuel through it and it seems to function fine. I do not completely rely on the wideband for tuning, more than anything it is a backup to what my butt is feeling and my ears are hearing. From what I have gathered through other people, most say to plan on the sensor lasting 15 hours or so. I only have the sensor in the exhaust for tuning and if I plan on going for a ride I will pull it out and toss a plug in the bung.

-

Wow, it's hard to believe it's been a year since I started this project. I never would have imagined that it would have caused the buzz it did, both good and bad sometimes. Going into the project I was extremely prepared and had an in depth background with four stroke EFI. After huge amounts of trials and tribulations I am still happy with my decision to convert the fuel and ignition system. No doubt though, it has been a ton of work and I have had to invest hundreds of hours to make it a success. I have learned so much that will be valuable to me elsewhere so I consider this a fun project no matter what the outcome is. The good thing is I am a stubborn bastard and will not give up on a project I start.

Now that we finally have had some cold weather lately I am getting into developing a cold weather tune along with my new R2's. I have never really talked about the tuning of the system, mainly the component selection and troubleshooting issues that cropped up. After tuning the engine this summer with the PT Mids on it and in Speed Density, I decided to swap over into AlphaN style tuning. There are some small differences between the two, but the largest is instead of fueling being controlled by RPM and manifold vacuum it is now controlled by RPM and throttle position.

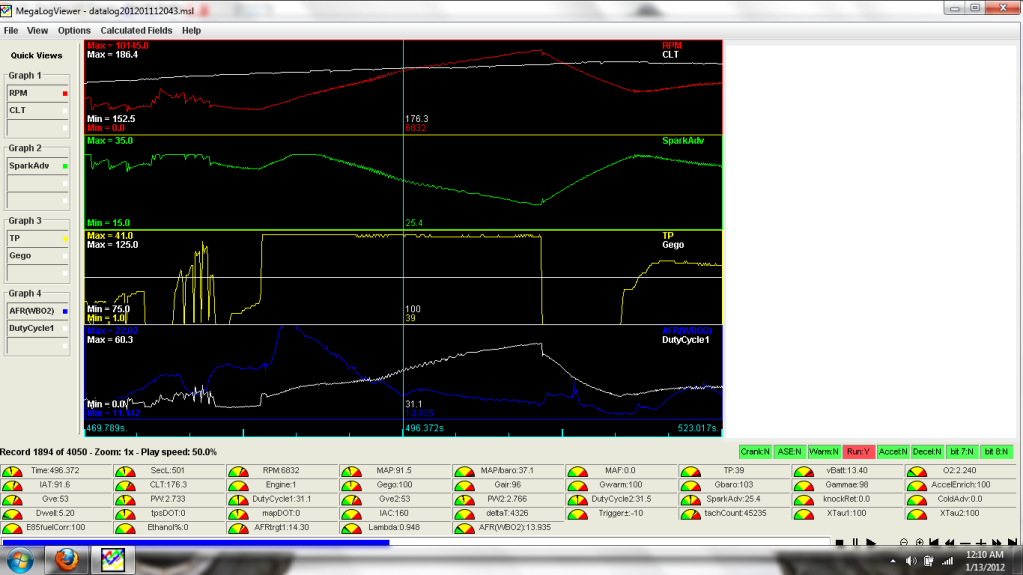

I posted a few screen shots below to keep the information plentiful. The first is a datalog of a part throttle run at 40%. The red line is engine RPM, white is coolant temperature, green is spark advance, yellow is throttle position, blue is air/fuel ratio, and the lower white line is injector duty cycle. I use the throttle limiter screw on the thumb throttle to target an area that I believe needs work. I run the engine just as you would on a dyno and from as low of a RPM as possible. I run all of my pulls in fifth gear and from 2500 to 10500 or so.

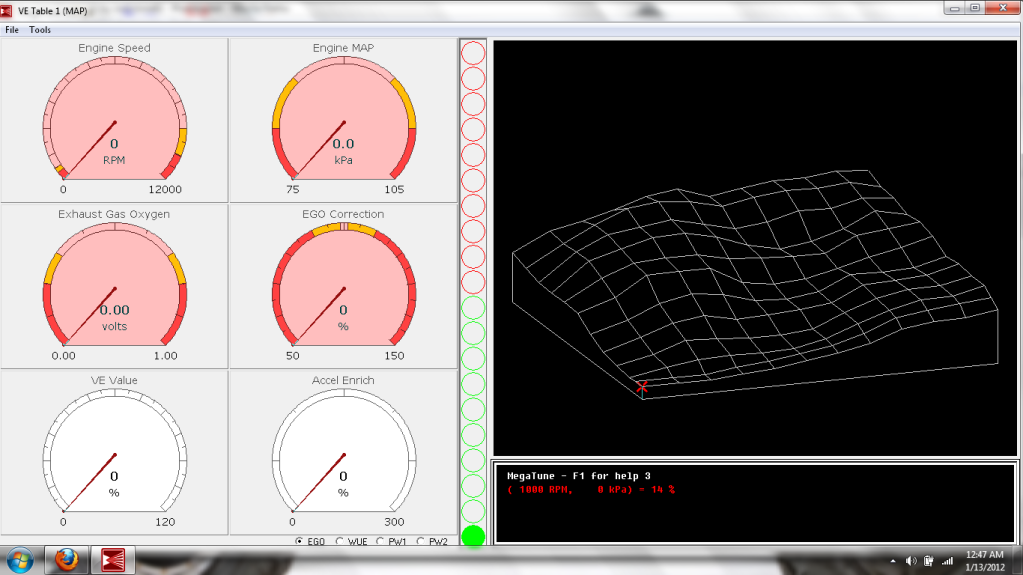

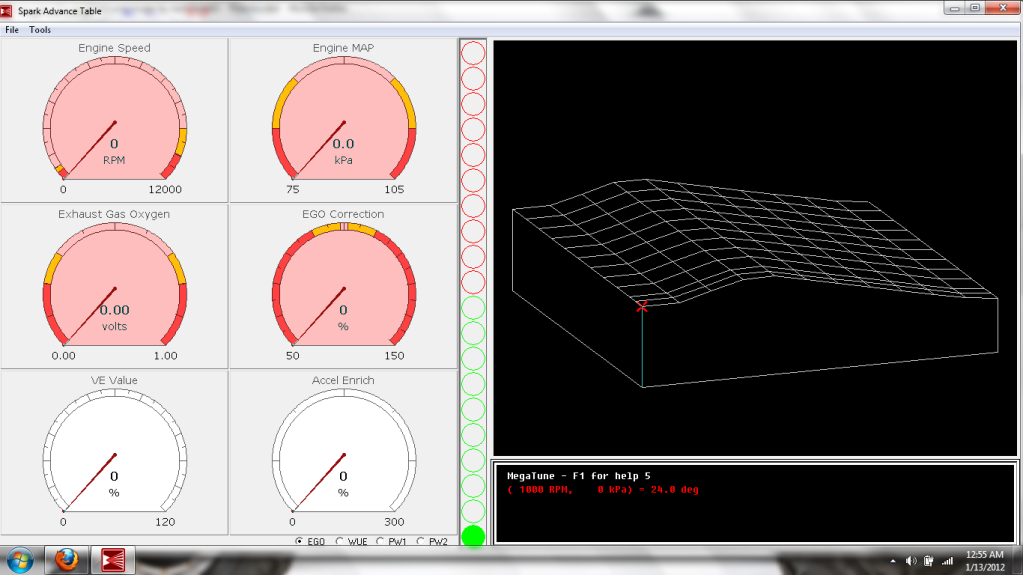

The next two shots are 3D representations of the VE map and the spark advance. Engine RPM is gaining from left to right, and throttle position goes from 0-100% towards the back on both maps. The spark curve is fairly simple, I took the factory curve as a baseline and added advance across the board just like a timing plate would do. Since then I have modified it a bit, but staying close to values that have worked well for me in the past.

The wideband has worked fairly well, with some quirks here and there. I recently had my first part failure which was the controller for the oxygen sensor. I sent the unit back to Innovate Motorsports since it was still under warranty and they checked it out. I just got an email here today saying a new controller is on its way back to me fully covered. I had some thoughts as to how the sensor would function at low RPMs, mostly thinking it would have problems with reversion. The sensor is extremely accurate from about 5000rpm and up, and I use it in conjunction with the plugs to get a tune. Below 5000rpm or so, the sensor reads lean and most of the tuning is done just like a set of carbs with throttle response and feel being the biggest contributions. The system is currently run in open loop which means the ECU looks at the air/fuel ration but does not do any correcting by it, another way of looking at it is the engine is running strictly off the programed values in the VE map.

The biggest change that I noticed from my carbs and stock ignition system is how smooth the engine is. It starts with one kick and will almost instantly settle into a rock solid 1800rpm idle. Then engine doesn't have the normal Banshee ring to it while not on the pipe. The old setup would run okay when not on the pipe, but with the new trigger wheel being so accurate and having that much more control of fueling and ignition in those areas it purrs like a four stroke kitten all day long down low. I have not specifically worked on throttle response, but it is all ready as good if not better than my Lectrons.

If I can find the GoPro and some batteries, I will post a video this weekend of her getting beat. As long as nothing breaks, a friend and myself were going to run down and ride Lake Winnebago with Nieskes and ChevyBanshee91 on Saturday or Sunday. Wish us luck! Evan

-

Don't forget that tire size also plays a role in shock length. The taller tire will require a shorter shock and vice versa for a shorter tire. Your best bet is to get your arms, and then check shock length with the desired tire at 1.5" frame height and then in the 11.5" to 13" range depending on travel desired.

-1" or -2" swingarm wanted

in Wanted

Posted

Thanks for the offer! I said screw it and cut down my current swinger by 1.5" just now so this thread is no longer needed..